Anyone who has built their own audio equiment will know how hum can frequently blight their setup - especially in the early stages of the build. Small signal sources like pre-amps are particularly prone to hum and it can originate from more than one place. Ground-loops, power-supply 'ripple' and electromagnetic inteference from transformers can all cause constant low frequency noise in our audio that is refered to as hum.

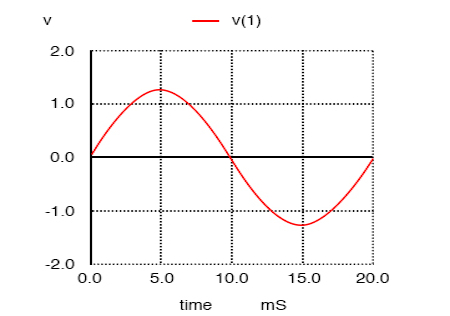

A 50Hz Wave - typical of Hum noise in audio. Note one wave cycle takes 20mS to complete

A turntable is particularly prone to picking up hum from elecromagnetic inteference. Where space is a constraint, a turntable and amplifier may find themselves within a few inches of each other. The cables from the turntable will often act like aeriels, picking up the electromagnetic energy from a nearby transformer or other devices.

Amplifier and Turntable - a few inches apart

Becasue a phono-stage or amplifier takes such a tiny signal from a phono-cartridge, the signal will be amplified many-hundreds of times to create an audible sound-wave. Tackling the problem from this 'end' ensures the signal is at least as clean as it can be before we start worrying about what might be happening in our downstream amplifier.

In this guide we present a simple and effective way to wire a turntable to ensure it is 'at least' blameless as a source of hum. The colloquial term for this method is called 'balanced wiring'. You don't need XLR sockets, nor do you need a balanced phono-amp. You will need, among other items, some 2-core instrument or microphone cable, some RCA plugs, a soldering iron and a couple of spare hours.

'Typical' Turntable wiring - L & R RCA plugs and earthing strap

Many turntables come with an earthing strap or wire. This is an addional wire that is connected to an earth terminal on the back of the amplifier or pre-amp. This earths the chassis and the tone-arm of the turntable. Disconnect this cable from an installed turntable and hear the hum resonate! The chassis and tonearm behave like aeriels, picking up EMI and other inteference that finds it's way into your signal. Unless we give it a path to ground that has a lower impedence than the signal path, this inteference will become part of the signal .. and that typically means audible hum.

The conventional way to wire a turntable (and the way most manufacturers do it) is to use two lengths of single core screened cable; one for each channel. The core inside the screen carries the positive portion of the cartridge's signal and the screen the negative. A cartridge is - in reality - a balanced signal source, but by grounding one side, we still get a perfectly amplifiable wave. The problem is that the screen can pick up inteference and EMI and this makes it's way back up to the cartridge and unbalances the signal. Noise picked up in the screen is now added to the output of the cartridge and this will be audible - usually as hum.

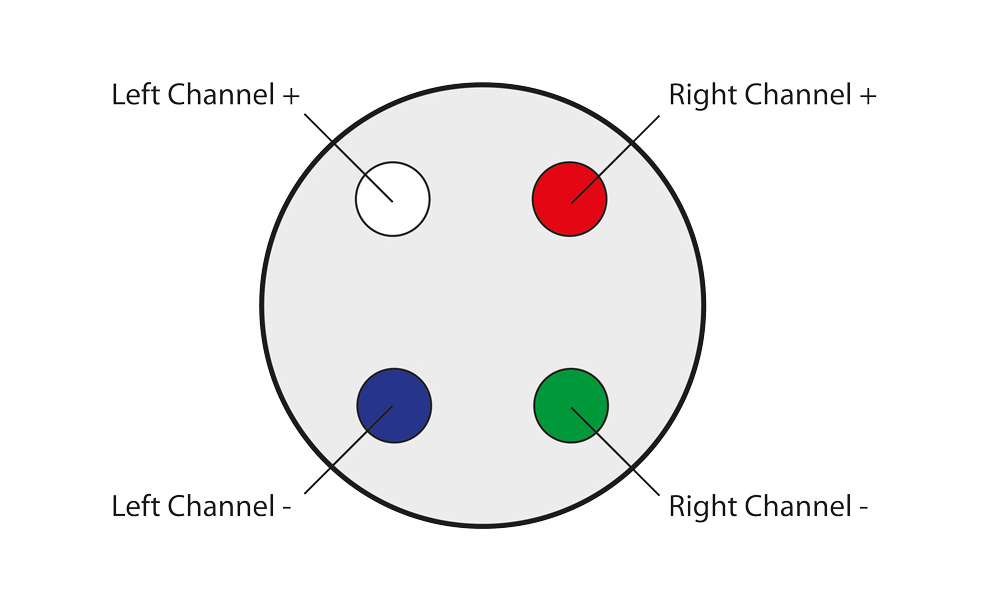

A phono cart is not grounded on the turntable - so it can be treated as a 'balanced' source

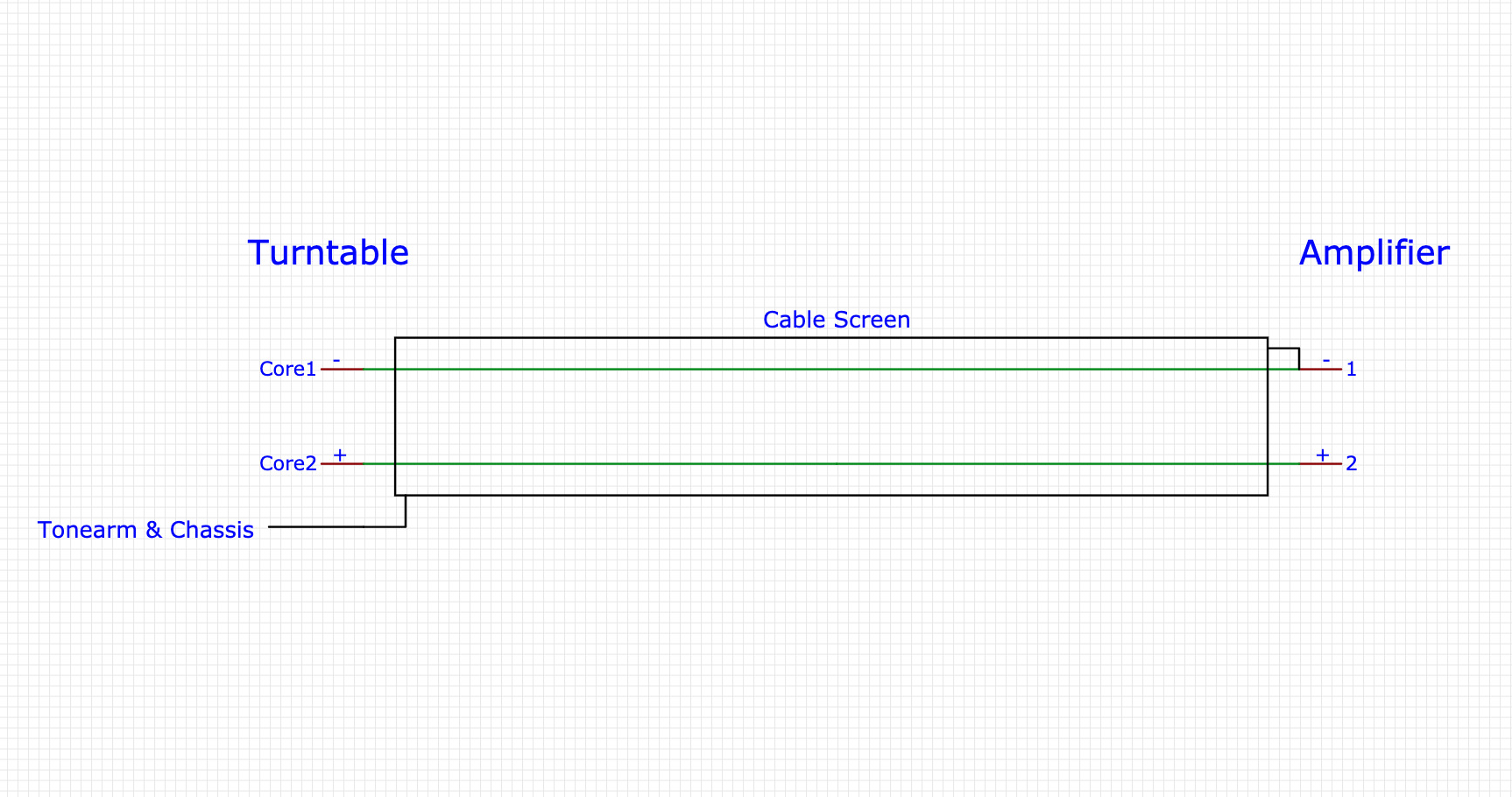

We can restore balance to signal source by using two cores inside the screen - one for the +ve and one for the -ve pole of the cartridge. The screen is connected to the negative core at the amplifier end and any noise it picks up finds it's way to earth rather than back up to the cartridge as that is it's new path of least 'resistance'.

The other useful feature of this arrangment is we can use the screen to replace the earth strap, without introducing any unwanted noise. By connecting the turntable end of the screen to the chassis/tonearm, we can send all of the inteference picked up by the tunrtable body to ground without using the audio signal as a conduit. As win-wins go, this is hard to argue with!

2-core screened cabling for Phono Turntable

The diagram above shows how the wiring is constructed. A pair of inexpensive RCA plugs and some 2-core screened instrument cable are all that is required. The negative wire from the cartridge is connected to the screen at the amp end. The screen is connected to the tonearm/chassis at the turntable end. Simple and effective.

If you're wondering why manufacturers don't do this, then the answer is that some actually do! Those that don't are probably motivated by the cost savings of using single-core screened cable. Added to that, most ready-made moulded RCA cables are made with single-core screened cable, so it's much easier to source inexpensive and robust cabling this way, rather than investing in bespoke RCA connectors.

Enjoy the results